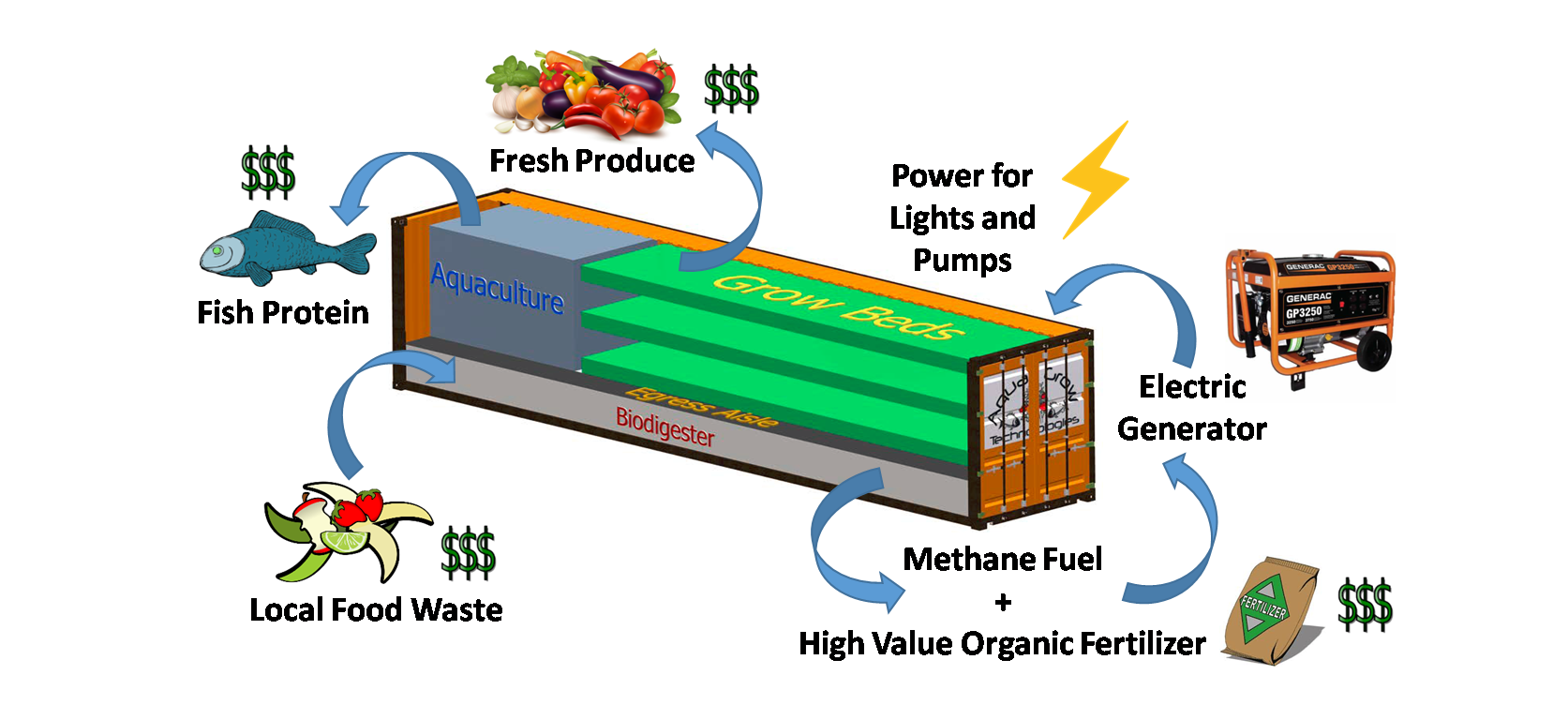

At AquaGrow Technologies we are developing a pioneering approach to scalable aquaponic farming through integration of the most advanced energy and precision control technologies for reliability, ease of use and increased productivity. Evolutionary improvements to farming technologies result from man's ability to control his environment. With adverse weather related effects on crop production predicted to increase, soil depletion and contamination, and scarcity of water resources, we believe another level of environmental controls need to be engineered and implemented for addressing the future global food production challenges.

By 2050 farmers will be asked to produce 70% more food than they do today

Aquaponics is a method of raising fish together with growing plants in a symbiotic environment. The name “aquaponics” derives from the combination of “aquaculture” (raising fish and other aquatic animals) and “hydroponics” (growing plants in nutrient-rich water). In such a system the fish waste nourishes the plants, and the plants clean the water, which is then returned to the fish. Thus water is circulated through the closed loop without significant loss to the environment. Both aquaculture and hydroponic are complex systems that require a fine balance of chemical and physical system parameters. One errant parameter can cause failure and eventually death in both fish and plants. Even though aquaponic systems have been demonstrated on a small scale commercial use of aquaponic farming is a very high risk proposition. Close monitoring of aquaponic system parameters coupled with accurate feedback system is required for successful large scale aquaponic food production. The size, complexity, and types of foods grown in an aquaponics system vary significantly and require dynamic operational modes.

Aquaponic Farming - the Future of Sustainable Food Production

Another challenge in aquaponic farming is high energy requirements, which significantly underpin the profitability of this sustainable farming approach. Fully enclosed aquaponic farms require electricity for artificial lighting, which on one hand enables stacking the grow beds vertically to increase the density of food productions, but on the other hand significantly adds to the operational costs. That is why most of the existing aquaponic farms utilize greenhouse enclosures to minimize the use of electricity for plant growth, which requires special semi-permanent installations, and relatively large square footage for operations. Typical payback time for an indoor aquaponic farm is 10-20 years, which is also a significant barrier to entering this field.

Integrated Sustainability is the Key to Resource Efficient Food Production and Continued Economic Growth

AquaGrow Technologies developed an innovative waste-to-energy-to-food approach that can solve high capital cost, low profitability and reliability challenges of aquaponic farming. By making aquaponics farms rather small scale and modular, we are lowering the entry barrier for farmers, assuming they can expand the scale of operations when small scale farm is successful. The projected payback time for a container farm is 2-3 years. The key to fast payback is net zero energy requirement achieved by integration of waste-to-energy conversion unit, and combination of multiple revenue streams in this new integrated farming approach.